The Growing Significance of China CNC Lathe Parts in Modern Manufacturing

The realm of manufacturing is continuously evolving, driven by advancements in technology and the ever-increasing demand for precision and efficiency. Among the key players in this landscape are China CNC lathe parts, which play a vital role in the production and manufacturing process across various industries. Understanding the importance of these components can provide valuable insights for businesses and manufacturers alike.

1. What Are CNC Lathe Parts?

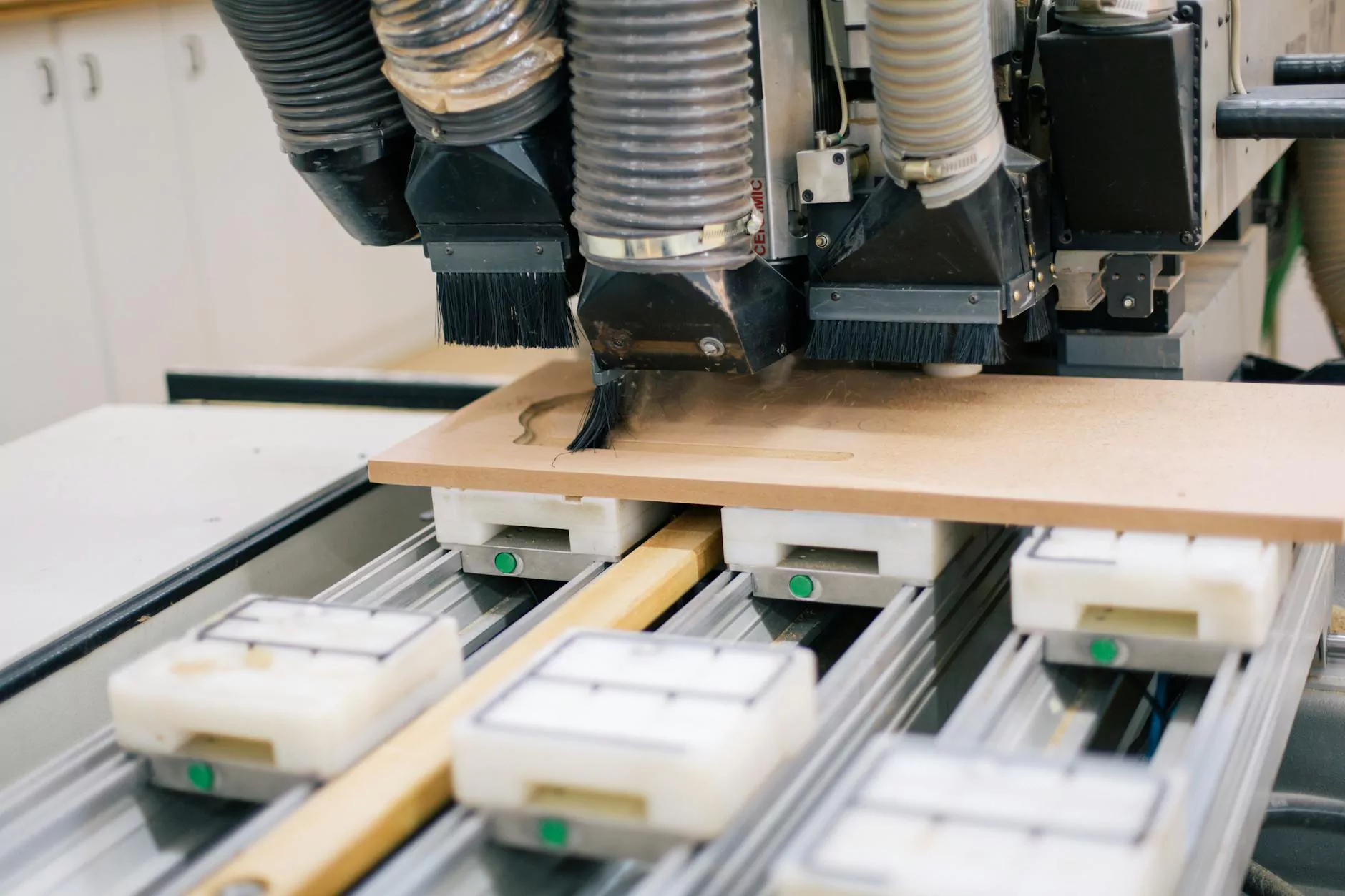

CNC lathes are essential machines used for cutting, shaping, and machining materials, primarily metals. The acronym CNC stands for Computer Numerical Control, which indicates the level of automation achieved in the machining processes. The components machined by these lathes, known as CNC lathe parts, encompass a wide variety of products. They include:

- Shafts: These are cylindrical components that transmit torque and rotation.

- Couplings: These parts connect two shafts together to transmit power.

- Housings: These enclosures protect internal components and provide structural support.

- Brackets: Used to support or hold components in place.

- Custom machined parts: Tailored to meet specific design requirements.

2. The Importance of CNC Lathe Parts

CNC lathe parts are integral to the fabricated products that shape our everyday lives. Their importance stems from several factors:

2.1 Precision and Accuracy

In industries such as aerospace, automotive, and medical, the need for precision is paramount. CNC machining allows for incredibly tight tolerances, ensuring that each China CNC lathe part is manufactured to exact specifications. This level of accuracy can significantly affect the performance and safety of the finished products.

2.2 Efficiency and Cost-Effectiveness

CNC machines automate the manufacturing process, reducing the time required to produce complex parts. This efficiency translates to lower labor costs and quicker turnaround times, making CNC lathe parts a cost-effective choice for bulk production.

2.3 Versatility Across Industries

The versatility of CNC lathe parts allows them to be employed in various sectors. From creating intricate prototypes to mass-producing components, the adaptability of these parts caters to an extensive array of applications.

3. The Role of China in CNC Machining

China has emerged as a significant player in the global CNC machining market. The reasons for this growth are multifaceted:

3.1 Manufacturing Excellence

Chinese manufacturers have invested heavily in state-of-the-art machinery and technology, capable of producing high-quality China CNC lathe parts. This commitment to excellence often leads to superior performance and durability of the components.

3.2 Competitive Pricing

The production costs in China often allow businesses to produce CNC lathe parts at a fraction of the price compared to Western counterparts. This cost advantage makes sourcing from China an attractive option for manufacturers looking to reduce expenses without sacrificing quality.

3.3 Robust Supply Chains

China's well-established supply chain network ensures that procurement processes are streamlined and efficient. With numerous suppliers and manufacturers in close proximity, companies can find the parts they need quickly and reliably.

4. Quality Standards: Ensuring Reliability

While the advantages of sourcing China CNC lathe parts are significant, quality assurance remains critical. Manufacturers must adhere to stringent quality standards to ensure that their products meet customer expectations. Key quality assurance practices include:

- ISO Certifications: Seek suppliers with ISO certifications that guarantee adherence to international quality management standards.

- Material Traceability: Ensure suppliers can trace the origins of materials used in production.

- Regular Inspections: Implement routine inspections to assess the quality and consistency of manufactured parts.

5. The Future of CNC Machining in China

The future of CNC machining in China looks promising, with several trends likely to shape its trajectory:

5.1 Adoption of Advanced Technologies

Technologies such as 5G, AI, and IoT will play crucial roles in enhancing manufacturing processes. The implementation of these technologies can lead to smarter factories, improved process efficiency, and overall better outcomes for China CNC lathe parts.

5.2 Increased Focus on Sustainability

As global awareness surrounding environmental issues increases, Chinese manufacturers are also beginning to prioritize sustainable practices. Implementing eco-friendly processes and materials will become increasingly important in attracting global clients.

5.3 Diversification of Markets

Manufacturers are testing new markets outside traditional sectors, including renewable energy and electric vehicles, where the demand for high-quality CNC laathing parts is on the rise. This diversification can lead to new opportunities and growth potential.

6. DeepMould: Your Trusted Partner in Metal Fabrication

At DeepMould, we pride ourselves on being at the forefront of the metal fabrication industry. We specialize in manufacturing and sourcing China CNC lathe parts tailored to your specific needs, providing:

- Customized Solutions: Our experienced engineers work closely with clients to design and produce components that meet precise requirements.

- High-Quality Assurance: Using cutting-edge technology, we ensure that our CNC lathe parts meet the highest industry standards.

- Efficient Production: With a robust supply chain and advanced machinery, we deliver products quickly without compromising quality.

7. Conclusion

As the manufacturing landscape continues to evolve, China CNC lathe parts will remain a cornerstone of efficiency, precision, and reliability. By leveraging the expertise of specialized suppliers like DeepMould, businesses can gain a competitive edge in today’s demanding market. Embrace the future of manufacturing with CNC technology and ensure your production processes are equipped with the finest components available.

For more information on our offerings and how we can assist you in your metal fabrication projects, feel free to reach out to us.